PRODUCT

صفحة رئيسية>منتجات>

كسارة Mali Gyratory 45 tph

Product datasheet Jaw Gyratory Crusher BK 63-75 Pro

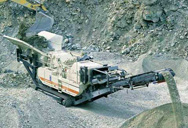

2023年9月7日 Product datasheet. Jaw Gyratory Crusher BK 63-75 Pro. High-performance crushing for capacities above 4,000 mtph. Jaw Gyratory Crusher Pro – the next generation of underground crushing. The main characteristic of jaw gyratory crushers is their enlarged feed opening, which is located on one side of the crusher only.2023年9月7日 High-performance primary crushing for capacities above 4,000 mtph. When it comes to crushing blasted hard rock in ore and natural stone mining, the eficiency of our gyratory crushers is second to none. Our KB Pro range is designed for high-performance primary crushing, with safe and easy maintenance by design.Product datasheet Gyratory Crusher KB-54-67 ProHeavy duty track unit with dual speed (optional) configuration. Safety guards in compliance with machinery directive. Sturdy walkway with handrails, kick board and access ladders. Dual power mode – flexibility to power the plant either by external electric connection or by on-board diesel generator power pack unit (optional).Track Mounted Jaw Crusher Manufacturer - Propel

Jaw Gyratory Crusher Pro

The Jaw Gyratory Crusher Pro is engineered to handle bigger chunks of material than comparable gyratory crushers of the same mantle diameter. This gives you greater flexibility in your crushing operation, and reduces the tendency for bridging in the feed zone.2022年7月6日 A gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant. Gyratory crushers are designated in size either by the gape and mantle diameter or by the size of the receiving opening. Gyratory crushers can be used for primary or secondary crushing.Primary Gyratory Crusher High Performance GY Series2019年9月10日 CG800i crushers ofer excellent reliability and safer faster maintenance – up to 30% faster than competing crushers. A robustly designed one-piece main shaft and reinforced shells are made for tough use. The one-piece spherical spider bearing ofers 5 times longer wear life than competing spider bushing design.SANDVIK CG800i GYRATORY CRUSHER SERIES

Gyratory Crusher (Gyratory Crushers Explained) - saVRee

Gyratory crushers typically crush to reduce the size of aggregate to a maximum of about one-tenth of its original size. Gyratory crushers are always installed vertically orientated. A gyratory crusher’s size is classified by: Its gape and mantle diameter. The diameter of the receiving opening. Gyratory Crusher Components2022年11月21日 Gyratory crushers. State-of-the-art technology with throughput rates of up to 14,000 t/h. 2. Our solutions for the hardest jobs. 3. Fields of application and design characteristics. When it comes to the crunch, crushing systems from thyssenkrupp Industrial Solutions offer the ultimate in performance, reliability and cost-effectiveness.Industrial Solutions Gyratory crushers - ThyssenKruppJaw and gyratory crushers are used for initial size reduction to convert big rocks into small stones. This is generally followed by a cone crusher. A combination of rod mill and ball mills are then used if the ore must be ground below 325 mesh (45 μm). Instead of grinding the ore dry, slurry is used as feed for rod or ball mills, to avoid dusting.Gyratory Crusher - an overview ScienceDirect Topics

Torque Analysis of a Gyratory Crusher with the Discrete

2023年7月18日 In this paper, a Metso 60-110 gyratory crusher of 1500 kW nominal power operating in a Chilean copper mine is modeled and simulated by using the discrete element method in order to study the crushing power and crushing torque under different operational2023年9月7日 Product datasheet. Jaw Gyratory Crusher BK 63-75 Pro. High-performance crushing for capacities above 4,000 mtph. Jaw Gyratory Crusher Pro – the next generation of underground crushing. The main characteristic of jaw gyratory crushers is their enlarged feed opening, which is located on one side of the crusher only.Product datasheet Jaw Gyratory Crusher BK 63-75 Pro2023年9月7日 High-performance primary crushing for capacities above 4,000 mtph. When it comes to crushing blasted hard rock in ore and natural stone mining, the eficiency of our gyratory crushers is second to none. Our KB Pro range is designed for high-performance primary crushing, with safe and easy maintenance by design.Product datasheet Gyratory Crusher KB-54-67 Pro

Track Mounted Jaw Crusher Manufacturer - Propel

Heavy duty track unit with dual speed (optional) configuration. Safety guards in compliance with machinery directive. Sturdy walkway with handrails, kick board and access ladders. Dual power mode – flexibility to power the plant either by external electric connection or by on-board diesel generator power pack unit (optional).The Jaw Gyratory Crusher Pro is engineered to handle bigger chunks of material than comparable gyratory crushers of the same mantle diameter. This gives you greater flexibility in your crushing operation, and reduces the tendency for bridging in the feed zone.Jaw Gyratory Crusher Pro 2022年7月6日 A gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant. Gyratory crushers are designated in size either by the gape and mantle diameter or by the size of the receiving opening. Gyratory crushers can be used for primary or secondary crushing.Primary Gyratory Crusher High Performance GY Series

SANDVIK CG800i GYRATORY CRUSHER SERIES

2019年9月10日 CG800i crushers ofer excellent reliability and safer faster maintenance – up to 30% faster than competing crushers. A robustly designed one-piece main shaft and reinforced shells are made for tough use. The one-piece spherical spider bearing ofers 5 times longer wear life than competing spider bushing design.Gyratory crushers typically crush to reduce the size of aggregate to a maximum of about one-tenth of its original size. Gyratory crushers are always installed vertically orientated. A gyratory crusher’s size is classified by: Its gape and mantle diameter. The diameter of the receiving opening. Gyratory Crusher ComponentsGyratory Crusher (Gyratory Crushers Explained) - saVRee2022年11月21日 Gyratory crushers. State-of-the-art technology with throughput rates of up to 14,000 t/h. 2. Our solutions for the hardest jobs. 3. Fields of application and design characteristics. When it comes to the crunch, crushing systems from thyssenkrupp Industrial Solutions offer the ultimate in performance, reliability and cost-effectiveness.Industrial Solutions Gyratory crushers - ThyssenKrupp

Gyratory Crusher - an overview ScienceDirect Topics

Jaw and gyratory crushers are used for initial size reduction to convert big rocks into small stones. This is generally followed by a cone crusher. A combination of rod mill and ball mills are then used if the ore must be ground below 325 mesh (45 μm). Instead of grinding the ore dry, slurry is used as feed for rod or ball mills, to avoid dusting.2023年7月18日 In this paper, a Metso 60-110 gyratory crusher of 1500 kW nominal power operating in a Chilean copper mine is modeled and simulated by using the discrete element method in order to study the crushing power and crushing torque under different operationalTorque Analysis of a Gyratory Crusher with the Discrete 2023年9月7日 Product datasheet. Jaw Gyratory Crusher BK 63-75 Pro. High-performance crushing for capacities above 4,000 mtph. Jaw Gyratory Crusher Pro – the next generation of underground crushing. The main characteristic of jaw gyratory crushers is their enlarged feed opening, which is located on one side of the crusher only.Product datasheet Jaw Gyratory Crusher BK 63-75 Pro

Product datasheet Gyratory Crusher KB-54-67 Pro

2023年9月7日 High-performance primary crushing for capacities above 4,000 mtph. When it comes to crushing blasted hard rock in ore and natural stone mining, the eficiency of our gyratory crushers is second to none. Our KB Pro range is designed for high-performance primary crushing, with safe and easy maintenance by design.Heavy duty track unit with dual speed (optional) configuration. Safety guards in compliance with machinery directive. Sturdy walkway with handrails, kick board and access ladders. Dual power mode – flexibility to power the plant either by external electric connection or by on-board diesel generator power pack unit (optional).Track Mounted Jaw Crusher Manufacturer - PropelThe Jaw Gyratory Crusher Pro is engineered to handle bigger chunks of material than comparable gyratory crushers of the same mantle diameter. This gives you greater flexibility in your crushing operation, and reduces the tendency for bridging in the feed zone.Jaw Gyratory Crusher Pro

Primary Gyratory Crusher High Performance GY Series

2022年7月6日 A gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant. Gyratory crushers are designated in size either by the gape and mantle diameter or by the size of the receiving opening. Gyratory crushers can be used for primary or secondary crushing.2019年9月10日 CG800i crushers ofer excellent reliability and safer faster maintenance – up to 30% faster than competing crushers. A robustly designed one-piece main shaft and reinforced shells are made for tough use. The one-piece spherical spider bearing ofers 5 times longer wear life than competing spider bushing design.SANDVIK CG800i GYRATORY CRUSHER SERIESGyratory crushers typically crush to reduce the size of aggregate to a maximum of about one-tenth of its original size. Gyratory crushers are always installed vertically orientated. A gyratory crusher’s size is classified by: Its gape and mantle diameter. The diameter of the receiving opening. Gyratory Crusher ComponentsGyratory Crusher (Gyratory Crushers Explained) - saVRee

Industrial Solutions Gyratory crushers - ThyssenKrupp

2022年11月21日 Gyratory crushers. State-of-the-art technology with throughput rates of up to 14,000 t/h. 2. Our solutions for the hardest jobs. 3. Fields of application and design characteristics. When it comes to the crunch, crushing systems from thyssenkrupp Industrial Solutions offer the ultimate in performance, reliability and cost-effectiveness.Jaw and gyratory crushers are used for initial size reduction to convert big rocks into small stones. This is generally followed by a cone crusher. A combination of rod mill and ball mills are then used if the ore must be ground below 325 mesh (45 μm). Instead of grinding the ore dry, slurry is used as feed for rod or ball mills, to avoid dusting.Gyratory Crusher - an overview ScienceDirect Topics2023年7月18日 In this paper, a Metso 60-110 gyratory crusher of 1500 kW nominal power operating in a Chilean copper mine is modeled and simulated by using the discrete element method in order to study the crushing power and crushing torque under different operationalTorque Analysis of a Gyratory Crusher with the Discrete

- amp اولیه b سنگ شکن ثانویه

- الإنتاج محطم منجم الفضة

- عملية كاملة من الكرة مطحنة عملية

- كسارة خط الصانع كسارة عقيمة

- komplet محطم للبيع في المملكة المتحدة

- ماشین آلات شن و ماسه سنگ در کرالا

- كيف يمكنني الحصول على آلة كسارات الحجارة

- هیدرولیک مخروط خرد کردن تولید ماشین 750t

- ماليزيا كسارة آلة كسارة للبيع

- طريقة طحن حبة البركة

- آلة لفرز الرمل و

- المشاكل على كسارة الفك

- وحدة كسارة الحجر المتنقلة في أوغندا

- محطم كسارة الحجر كسارة العرض

- محاجر الصخور الجاهزة الفجيرة

- الحجر ريموند مطحنة الأسطوانة

- زراعة النباتات تحت الضوء الصناعي

- آرتي آلات طحن على الوجهين

- على بو المعدات كسارة متنقلة

- تاميل نادو الفك محطم